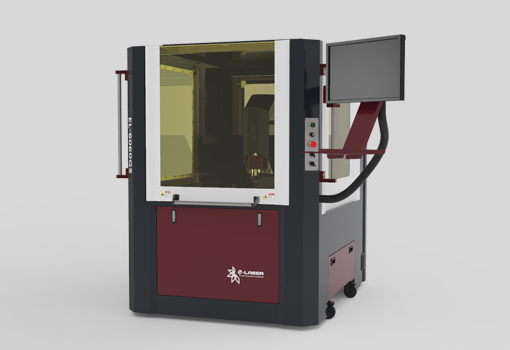

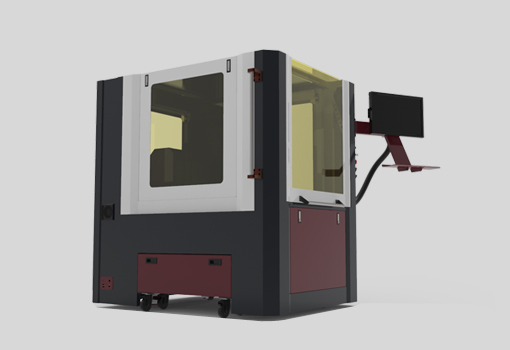

EL-6060GS CNC

The EL-6060GS is a compact CNC machine that can be machined in a small space such as a university, laboratory, laboratory or small workshop.

We have excellent durability based on bed heat treatment process and precision machining process through direct design, and metal materials such as aluminum can be precisely / continuously processed.

Depending on the material to be machined, it is possible to select the bonded spindle and the gantry structure is applied to enable efficient working space.

It adopts high performance servo motor as standard and maximizes work stability and efficiency by installing Korean control program. In order to provide user convenience, we provide various types of machined JIG based on years of experience and promise stable technical support after installation of equipment until the first production.

All of our products can be customized according to your needs and work environment.Specification

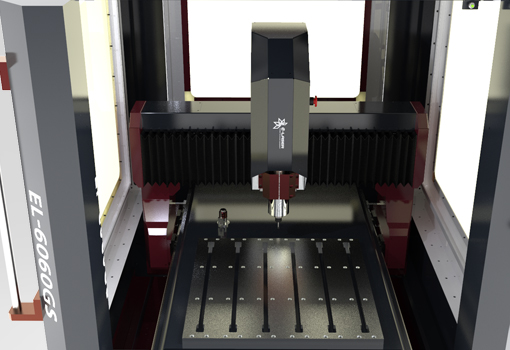

- Machining area600x600x150㎜(z)

- Table typevT-slot (option: vacuum table)

- Operating voltage

AC 220V 60Hz single phase

AC 380V 60Hz three phase - Maximum number of revolutions

~ 50000rpm

- Spindle capacity1.1KW~6KW

- Drive typeDirect high frequency spindle

- ColletER16

- Transport motorServo motor

- Transport speedMax 12m/min

- Transport DeviceBall Screw, LM Guide

- Repeatability0.005mm

- Accuracy of movement0.01mm

- ControllerController made by Korea

Function

- High rigidity frame structure

High rigidity frame structure enhances

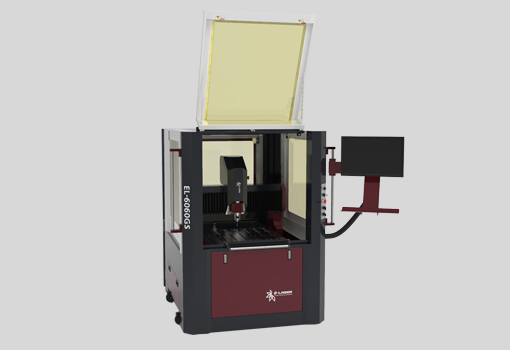

equipment stability - Gentry type structure

Gentry type structure for convenient working

environment - T-slot bed applicationConvenient and variety clamping environment

- High precision ball screw application

High precision ball screw is used for more accurate

machining quality - High output spindle

High frequency inverter enables high speed

rotation of tens of thousands of RPM - Automatic tool height sensor

Automatically measures the height between the

material and the tool after mounting the end mill - Applying controller made in Korea

Various controls such as absolute origin, block skip,

precedent control - One year warrantyOur standard warranty period.

- Customizable

Customized development of various jigs and

special spindle applications

Video

Features of equipment

-

High strength gantry structure

By adopting a high strength gantry structure, stability and convenience of operation are added.

-

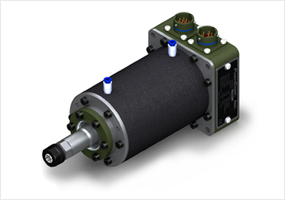

High precision servo motor application

Precision machining is possible by using high-quality precision motors

-

One-touch tool change application

With one-touch tool changeable spindle, it is possible to replace tool quickly, eliminating various troubles.

-

Domestic controller applied

By applying the CNC multi-axis controller of Korea, stability of control and localized software are added to the convenience of work.

Option

-

Variable spindle applicable

You can select spindles that match the characteristics of the job by torque, RPM, and output.

-

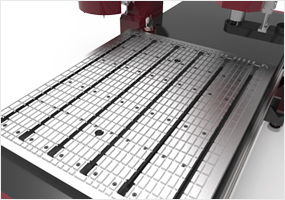

T-slot or Vacuum bed selection

T-slot bed is used as standard and vacuum clamping bed can be selected as an option.

-

Control system selectable

As a standard, Korean-made controller is applied and high-performance controller such as Siemens, FANUC can be applied according to customer's demand.

Also available for general purpose NC studio. -

Custom production possible (special function)

To fulfill the functions required by the customer for special purposes such as Machine Vision Device configuration is possible.

Material processing samples

-

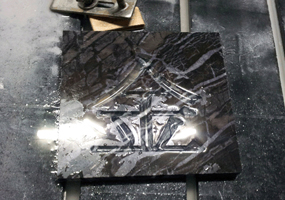

Stone

-

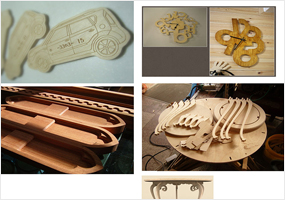

Plastic

-

Metal

-

Wood and Natural Materials