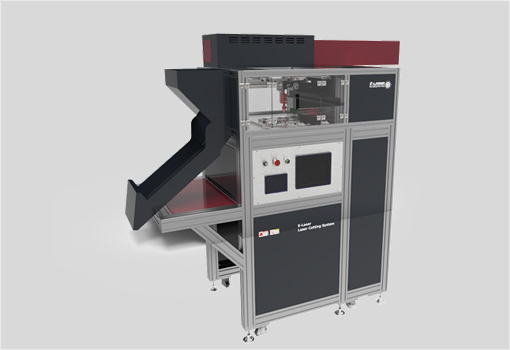

Injection gate laser cutter FA system

TV diffuse and aspherical lenses Precision optics lenses Gate cutting during injection molding has a great impact on the quality of automated assembly and optical lenses.

Elaser is capable of cutting without deterioration or dust at the current gate length of 0.2 mm ± 0.05 mm. In addition, it is possible to implement one laser cutting machine per two injection machines as well as one machine per injection machine.

The advantage is the low cost of maintenance due to the low cost DC type CO2 laser, and the maintenance cost is also low.

The dust collector is installed as a basic structure to absorb the dust immediately, and it can be linked with the logistics automation system such as existing conveyor.

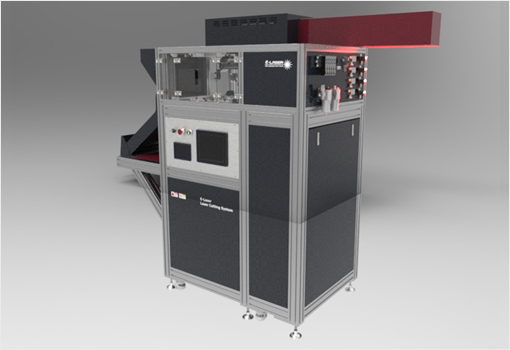

It is possible to reduce the labor cost remarkably by linking with other vision inspection equipment and it is easy to change processing data through PC.

Specification

- Machining area 300 x 300m (custom made)

- Cutting error range 0.2mm±0.05

- Resolution 0.025mm

- Repeatabilit 0.01mm

- CAM Program E-Laser Cut 8.0

- Laser10.6nm CO2 Laser (DC glass tube 150W)

- Data commandPLC program, internal language

- Power supply AC 380V 3P 60Hz

- Drive system Servo motor + Ball screw

- One year warrantyOur standard warranty period.

Video

Features of equipment

-

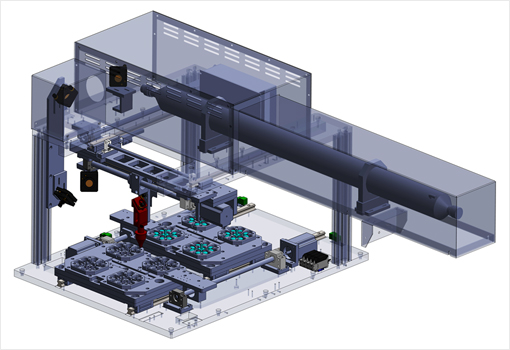

Twin gantry structure

Two gantry structures, each equipped with a gantry laser and spindle, allowing them to work without interference and contamination.

-

2: 1 (Injection machine: equipment) control

2: 1 control is possible, making it more economical. You can build automation lines.

-

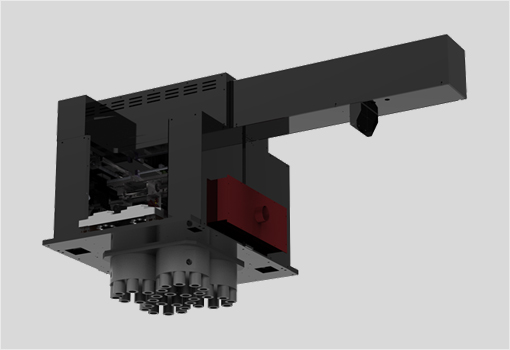

High precision ball screw is used

Precision machined ball screws minimize misalignment and minimize overload displacement errors.

-

AC Servo Motor Application

Precision machining is possible by using high quality precision motors.