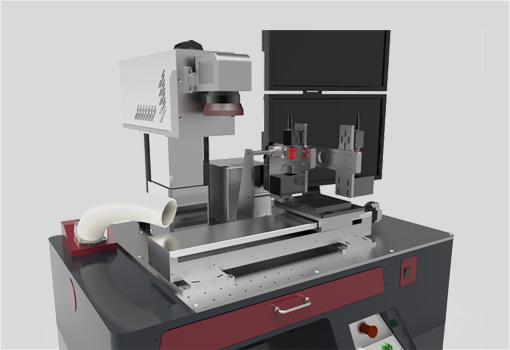

Machine vision marking system FA system

Precise micro-scale work using a laser scanner is impossible to see and work with the naked eye. Therefore, machine vision equipment is essential for laser work requiring micro-precision.

We have developed a machine vision marking system that fully meets these needs. By controlling one camera or two cameras, a control system has been constructed to work exactly wherever the position of the workpiece changes.

It is a system that can be mass-produced by applying to an automation line. It is convenient to use and operation.

All of our products can be customized according to your needs and work environment.Specification

- Vision camera

500,000 ~ 2,000,000 pixel monochrome or

color camera - lightingcoaxial lighting or side lighting

- Alignment stageShortening / X, Y, Z, R Vision alignment stage

- Drive systemLiner Motor or Air bearing Stage

- Vision Control

Camera and Illumination Dedicated Control and

Computation Control - Scanner / Laser controlRTC4 or RTC5 based control

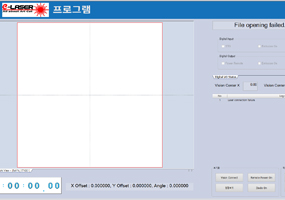

- Integration programLaser + Scanner + Vision integration only program

- Supported computer operating system

Windows 7 or later

- Power supplySingle phase 220V 60Hz 2200W

Function

- Various machine vision application

Position, alignment, etc. can be applied.

- Wide range of laser applications

1064nm, 355nm, 532nm etc, Applicable to

various wavelength lasers - Precision difference application

Apply various alignment stages according to

precision and characteristics - Multi language support

Support for multiple languages such as English,

Japanese, German, Chinese - Convenient alignment of the vision

Convenient alignment of the vision due to

the design of the mechanism suitable for

the automation line - Integration program development

RTC-based laser, scanner, vision control integrated

program application - Customizing possibility

equipment modification according to user's

requirement (automation equipment) - 1 year warrantyOur standard warranty period.

- Operational knowhow Education

Experts Conduct Customized Training for

Your Customers

Video

Features of equipment

-

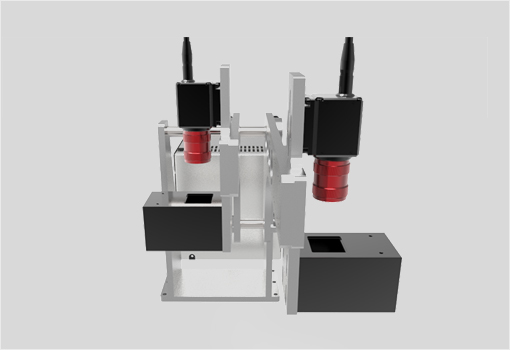

Applying high resolution camera

Applying one or more high resolution camera from 500M pixels to 200M pixels can perform desired machine vision function

-

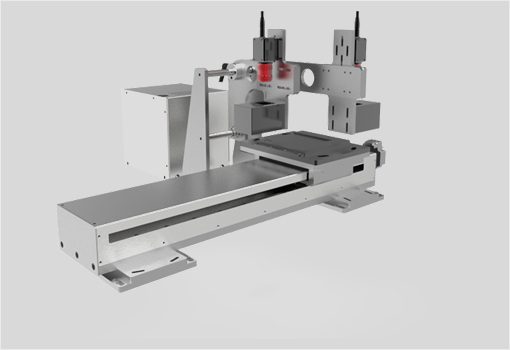

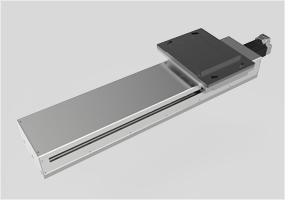

Precision stage application

Linear motor is applied to reduce misalignment. Optical table + Platen + Air bearing stage can be applied to minimize tolerance.

-

Integration Program

We have developed a program that can control laser, scanner and vision (based on RTC4 or RTC5).

-

Applicable to various equipments

Applicable to automation equipments or stand-alone equipments and can be designed so that the machine parts and machine vision can operate correctly.