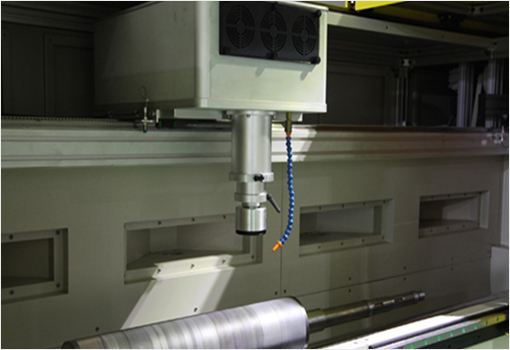

Anilox drum cleaner FA system

When using Anilox, cleaning with only solvent is limited. Several attempts have been made to overcome the limitations of cleaning with solvents, one of which is sanding with soda flour. However, it is difficult to clean completely, dust is blown away, environment is not good, and workability is also quite inefficient. Therefore, there are laser cleaning methods that can reliably solve these difficult tasks.

As a result, the characteristics of the laser washing machine developed by the company do not create by-products harmful to the environment, such as dust during cleaning with this equipment. Simply put the Anilox drum on the machine by automating the process, you can complete the process without any operation and no additional consumables are required.

The equipment has a long life and operates for about 100,000 hours without any maintenance.

This equipment is more convenient because it can be freely adjusted for washing speed and laser strength. To protect expensive Anilox drums, a triple safety device is installed to prevent damage to the Anilox drum in any case of equipment problems.

Specification

- Laser Fiber Laser MOFA type / CW type 20W

- Laser wavelength 1064nm ~ 1070nm

- Galvanometer X axis galvanometer motor + 1 mirror

- F-theter lensF254 or higher

- Controller Self-manufactured controller

- Laser Swing Width15mm or less

- Maximum cleanable

drum size1800 mm or less

- Maximum cleanable

drum diameter600 Ø

- Equipment weight600Kg or less

- One year warrantyOur standard warranty period.

동영상

Features of equipment

-

Long life, low maintenance costs

With 100,000 hours of Fiber Laser, maintenance costs are reduced because it has a long life and requires no solvents or gases.

-

Eco-friendly facilities

It is very environmentally friendly because it does not use or remove harmful substances compared to the existing cleaning methods.

-

Anilox drum protection

The laser control system ensures that expensive drums are not damaged during operation.

-

Maximize efficiency of your work

Put a drum on the device to complete the work, so there's less personnel lost.

Speed your work and streamline field operations.