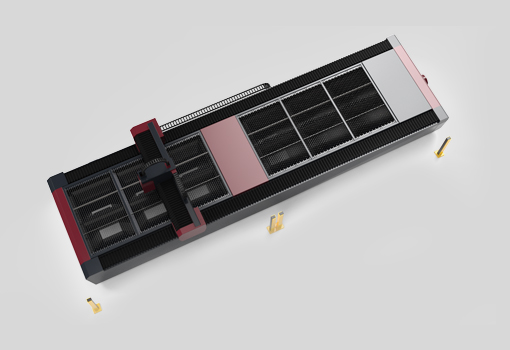

EL-1530LKMD Fiber

The EL-1530LKMD is dedicated to metal machining and has a maximum machining area of 1500 * 6000 (mm).

It is a device that rationally improves table exchange time and maintenance problem which is the problem of general EXCAHNGE-TABLE type equipment.

Maximum machining range 1500 * 6000 (mm) can be 2 divided and 1500 * 3000 (mm) standard materials can be processed sequentially without changing work table, maximum machining area reaches 1500 * 6000 (mm), it is possible to respond smoothly to non-standard work such as roll type.

To ensure stability during loading/unloading of materials, a triple safety device was adopted to ensure safety of workers, including the prevention of movement of nonoperating areas of laser heads during sequential processing.

Fiber optic technology for metal processing is applied and Laser Gas Ragulator which can control up to 30 bar is applied for quick switching of cutting gas and accurate pressure control. It can be operated with high power because it can mount 4kW or more fiber laser. The laser life is 100,000 hours and is semi-permanent.

All of our products can be customized according to your needs and work environment.Specification

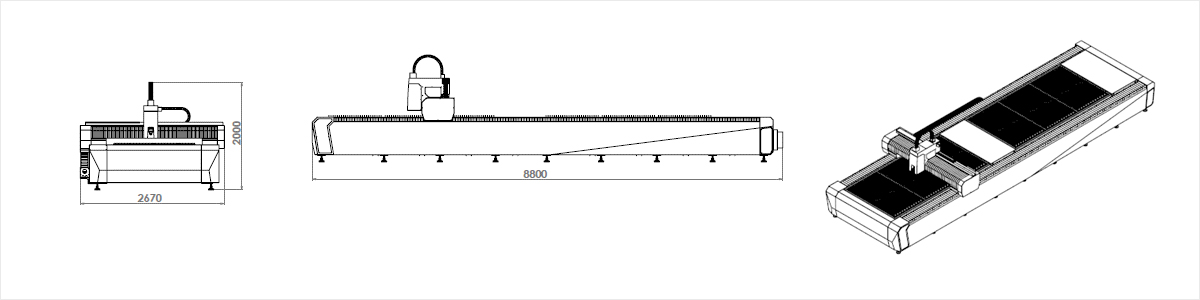

- Machining area1500 x 3000mm

- Maximum transfer speed120m/min

- Maximum cutting speed60000mm/min

- Position accuracy±0.1mm/3,000mm

- Repeatability±0.03mm

- CAM programcypcut(default), Lantek, actcut (option)

- Data input methodUSB interface direct connection, USB memory

- Supported computer

Operating systemWindows 7 or later Windows10

- Laser1064nm, Fiber Laser

- Drive systemRack&pinion+servo motor system(default)

- Power supply3 phase 380V 60Hz

Cutting Capacity (mm)

| Laser output | Mild steel | Stainless | Aluminium | Brass |

|---|---|---|---|---|

| 700W | 7.4 | 3 | 2 | 2 |

| 1KW | 12 | 6 | 6 | 5 |

| 2KW | 19.3 | 8 | 8.5 | 7 |

| 3KW | 20 | 11.3 | 12 | 10.5 |

| 4KW | 25 | 16 | 16 | 12 |

Video

Features of equipment

-

High rigidity frame

High rigidity frame application To Minimize vibration by applying high rigidity main frame.

After a heat treatment process of more than 3000 degrees to Minimized distortion. -

Excellent cutting performance

It boasts superior cutting performance and cutting speed compared to CO2 laser.

Fiber laser has a lifetime of 100,000 hours.

Maintenance costs are also very low. -

Highly reflective non-ferrous metal processing possible

The patented fiber laser technology cuts off the reflected light from the metal, so it can safely process the high-reflection metal that could not be processed by conventional fiber laser such as copper, aluminum, gold, silver and brass without damaging the laser.

-

Application of Laser Gas Regulator

It is possible to adjust the cutting gas pressure precisely by applying the special gas regulator and it is possible to control the pressure of oxygen, nitrogen, compressed air up to 30bar.

Option

-

Selectable Linear Motor System

By default, servo + Rack & pinion system is applied. Optional Linear Motor system is available.

The linear system can simplify the structure of the mechanism and enable more precise machining. -

Variety of lasers available

You can apply various lasers according to work purpose, material characteristics, laser output, manufacturer, according to your desired configuration.

-

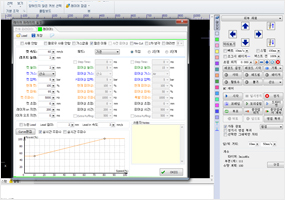

Dedicated controller and program selectable

You can choose various controllers and operating programs according to customer's needs.

All operating programs are made with Korean and easy to use. -

Dedicated Selectable Fiber laser Head

Suitable laser head can be applied according to working purpose, material characteristics and laser output.

Dedicated laser head is an important part, so we will decide through consultation.

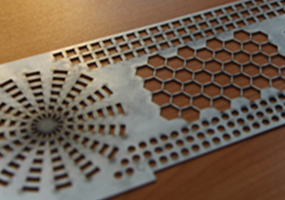

Material processing samples

-

Metal

-

Non-Metal