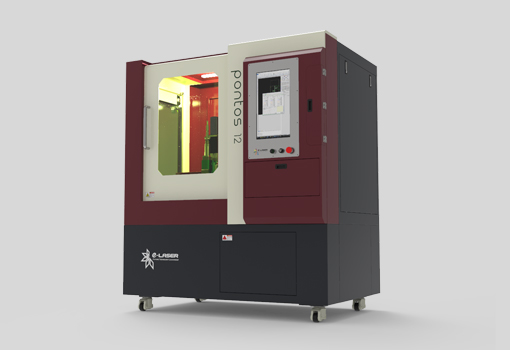

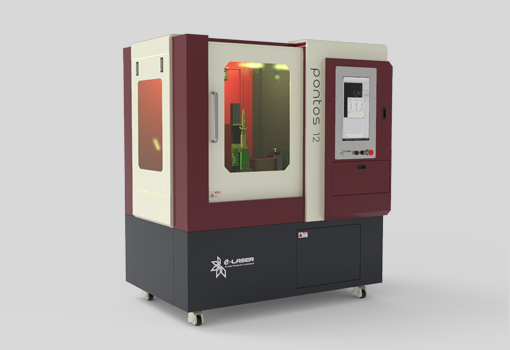

Pontos12 Fiber

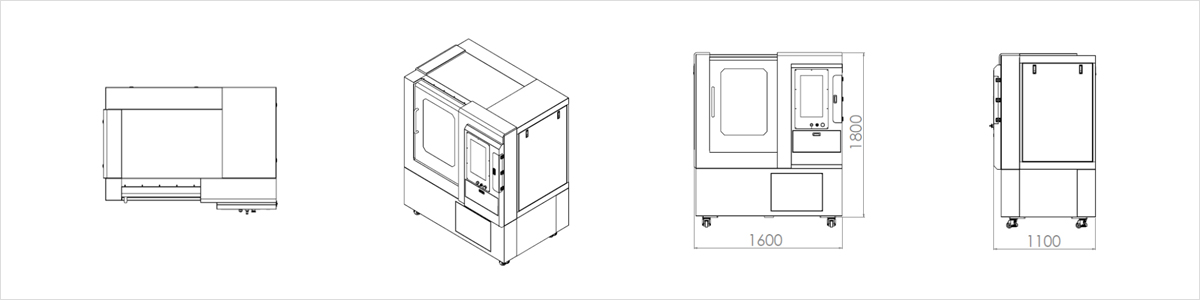

Compared to co2 lasers, the use of fiber lasers has been rapidly increasing due to the superior machining effect, and the demand for smaller machining ranges and precision machining is increasing. In response to the demand for small metal workpieces, especially for universities, laboratories, corporate research centers, and precious metal processing companies, E-Laser has introduced the Pontos 12, super compact device with a 300 * 300 mm process area using fiber optic lasers.

Linear motor system or Rack & pinion + Servo motor system is applied to make precise machining. Safety full cover and special coated glass are included.

Fiber optic technology for metal processing is applied. For fast switching of cutting gas and accurate pressure control Laser Gas Ragulator controllable up to 30 bar.

Laser oscillator can be applied from 300W to 4KW depending on the working purpose.

All of our products can be customized according to your needs and work environment.Specification

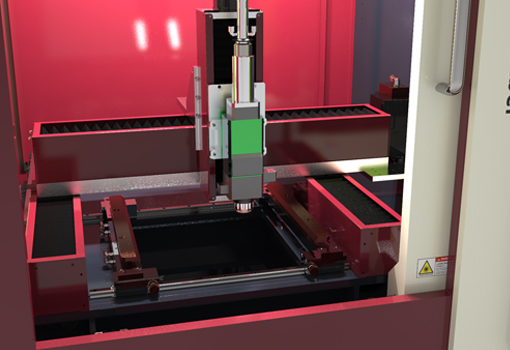

- Machining area300 x 300mm

- Maximum speed120m/min

- Maximum cutting speed60000mm/min

- Position accuracy±0.1mm/3,000mm

- Repeatability±0.03mm

- CAM programcypcut(default), Lantek, actcut (option)

- Data input methodUSB interface direct connection, USB memory

- Supported computer

Operating systemWindows 7 or later Windows10

- Laser1064nm, Fiber Laser

- Drive systemRack&pinion+servo motor system(default)

- Power supply3 phase 380V 60Hz

Cutting Capacity (mm,max)

| Laser output | Mild steel | Stainless | Aluminium | Brass |

|---|---|---|---|---|

| 700W | 7.4 | 3 | 2 | 2 |

| 1KW | 12 | 6 | 6 | 5 |

| 2KW | 19.3 | 8 | 8.5 | 7 |

| 3KW | 20 | 11.3 | 12 | 10.5 |

| 4KW | 25 | 16 | 16 | 12 |

Video

Features of equipment

-

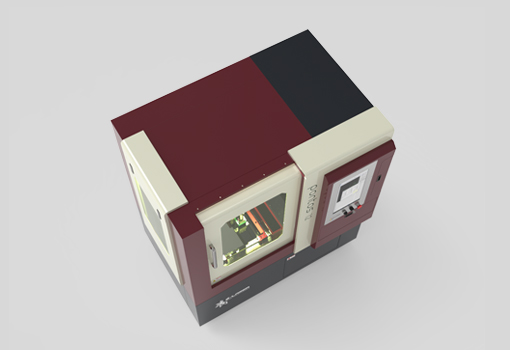

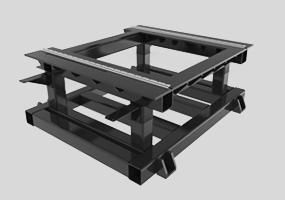

High rigidity frame

High rigidity frame application To Minimize vibration by applying high rigidity main frame. After a heat treatment process of more than 3000 degrees to Minimized distortion.

-

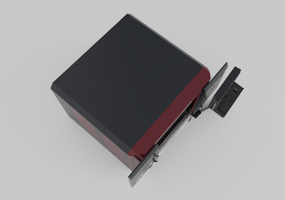

Safety full cover

Due to the nature of the fiber laser, there are risk of injury or fire to the worker or sparking fire due to reflection of laser light when processing metal. In order to prevent this, we have applied Full Cover to cover the whole equipment.

-

Highly reflective non-ferrous metal processing possible

The patented fiber laser technology cuts off the reflected light from the metal, so it can safely process the high-reflection metal that could not be processed by conventional fiber laser such as copper, aluminum, gold, silver and brass without damaging the laser.

-

Application of Laser Gas Regulator

It is possible to adjust the cutting gas pressure precisely by applying the special gas regulator and it is possible to control the pressure of oxygen, nitrogen, compressed air up to 30bar.

Option

-

Selectable Linear Motor System

By default, servo + Rack & pinion system is applied. Optional Linear Motor system is available.

The linear system can simplify the structure of the mechanism and enable more precise machining. -

Variety of lasers available

You can apply various lasers according to work purpose, material characteristics, laser output, manufacturer, according to your desired configuration.

-

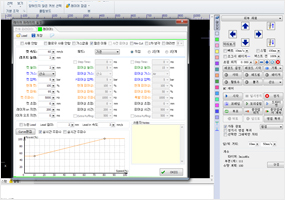

Dedicated controller and program selectable

You can choose various controllers and operating programs according to customer's needs. All operating programs are made with Korean and easy to use.

-

Dedicated Selectable Fiber laser Head

Suitable laser head can be applied according to working purpose, material characteristics and laser output.

Dedicated laser head is an important part, so we will decide through consultation.

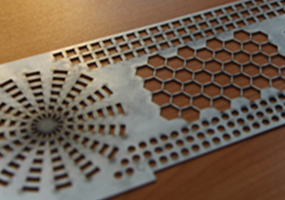

Material processing samples

-

Metal

-

Non-Metal