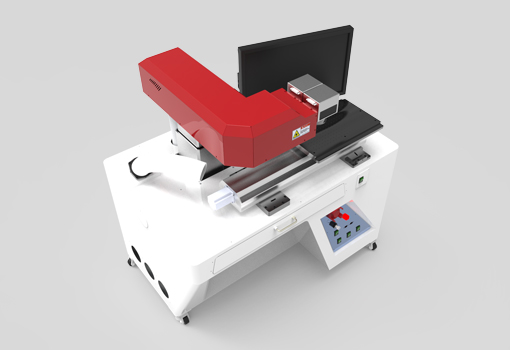

Spring Precision Cutter Custom Order Product

Two precision scanners are simultaneously processed and the processing speed is excellent. The operation area can be enlarged by operation of the short axis stage.

It is possible to control with less than 1um accuracy and it is easy to fix the material because it is equipped with a vacuum bed.

Optionally, additional coaxial vision accuracy can be achieved.

The remaining processes except material loading / unloading are fully automated. (Optional process automation possible)

All of our products can be customized according to your needs and work environment.Specification

- Machining area210 x 480mm (changeable)

- Laser typeFiber Laser Mopa type

- Laser wavelength1064~1070nm

- Laser output20W

- Repeatability0.5um

- Cooling systemAir-cooled (default)

- Supported computer operating system

Windows 10 32bit

- CAM programSelf-developed laser program + PLC program

- Max marking speed2500mm/s (default)

Function

- Automation systemCore Laser Equipment in Automation Line

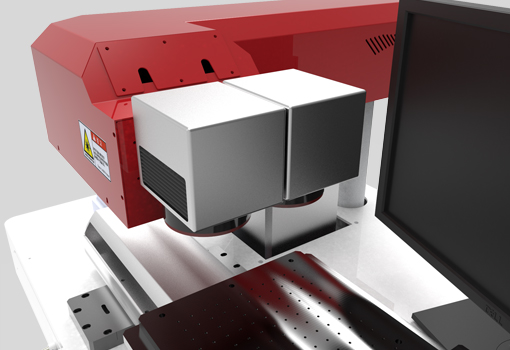

- Apply 2 precision scannersTwo high-quality precision scanners

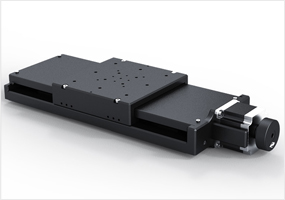

- Precision StagePrecision stage application for position alignment

- Multi-language support

Support for multiple languages including English,

Japanese, German, and Chinese - Convenient Focus alignment

Z axis lift application with precise control

- Using various lasersStructural design for various types of laser sources

- Customizing possibility

Equipment modification according to user's

requirement - 1 year WarrantyProvided Our standard warranty period.

- Operation Knowhow

Educational specialist conducts tailored training

for your clients

Video

Features of equipment

-

Twin Scanner Application

Two precision scanners are arranged in parallel to increase the machining area and increase efficiency.

-

Application of precision stage

By applying a stage with minimized tolerances.

Machining can be done so that the edges do not overlap. -

Precision Focus Control Lfit

Z axis precision lift is applied to precisely align the laser focus.

-

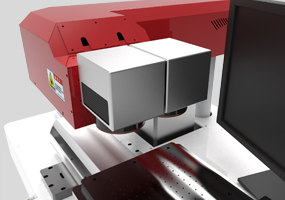

Application of Fiber Laser MOPA type

MOPA type fiber laser of 1064nm wavelength is used to cut the copper foil to increase the workability.