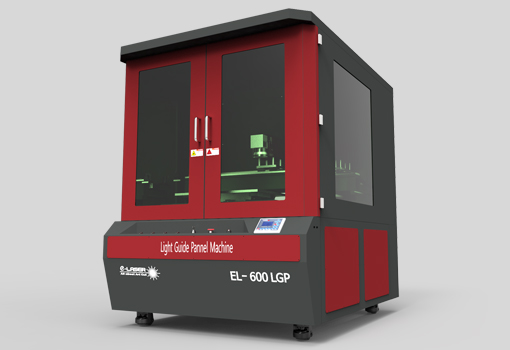

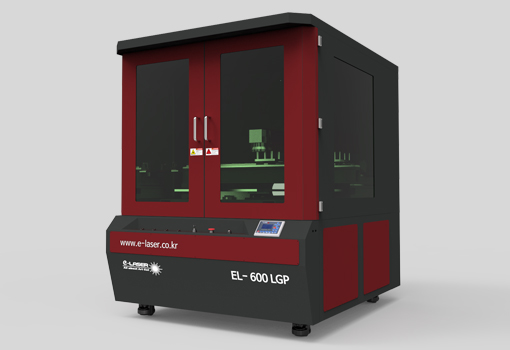

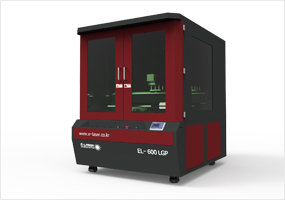

Light guide plate maker Custom Order Product

It is a device to fabricate LED diffuse light guide pattern by combining X, Y, Z Axis and Scanner with 10.6nm or 9.3nm CO2 laser and tool charger.

Unlike conventional methods, it is possible to produce very delicate and sophisticated patterns, and it is gradually becoming a popular trend.

By combining the axis and the scanner, we have achieved a wide machining area and quick workability.

Specification

- Machining area600 x 600mm

- Maximum machining speed

60000mm/min

- Resolution0.025mm

- Repeatability0.01mm

- CAM program

Axis device and scanner integrated control -

System controller self development - LaserCO2 Laser DC / RF, 10.6nm / 9.3nm

- Data input methodUSB interface direct connection, USB memory

- Drive systemservo+ballscrew+scanner

- Power supplyAC 380V three phase

Function

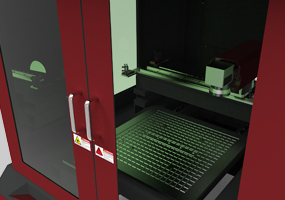

- Full Cover Application Full cover to prevent danger during processing

- Precision motorHigh quality servo motor application

- Precision Scanner Application

Excellent quality with high quality scanner

- Dedicated pattern

programEquipped with a dedicated program for patterning

of light guide plate - Ballscrew type

Durable ball screw application ensures stable

machining quality - Red beam pattern display

Convenient function to show processing pattern

with red beam - Variety of lasers availableVarious wavelengths of CO2 Laser can be selected

- 1 year warrantyOur standard warranty period.

- Operation Knowhow

Educational specialist conducts tailored training

for your clients

Video

Features of equipment

-

Application of precision servo motor

Precision machining is possible by using high quality precision motors.

-

Precision Scanner Application

Using a precision galvanometer-applied scanner, it achieves fast and accurate quality.

-

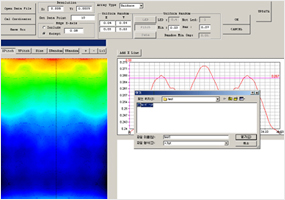

Dedicated pattern program

It is a program to compose a pattern by automatically calculating diffusion pattern according to processing size.

-

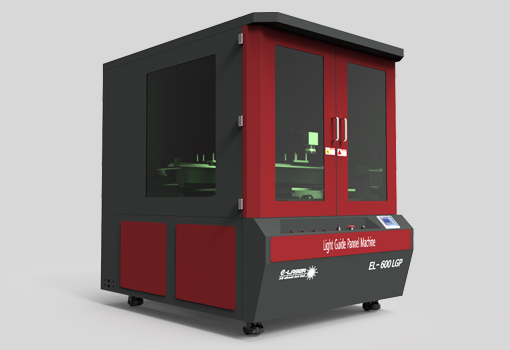

Full cover application

Full cover has been applied for operator's safety and work environment.