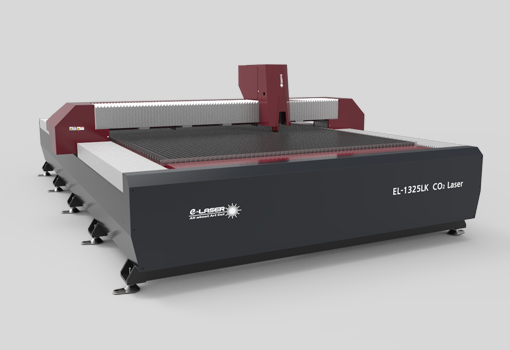

Large CO2 laser equipment Custom Order Product

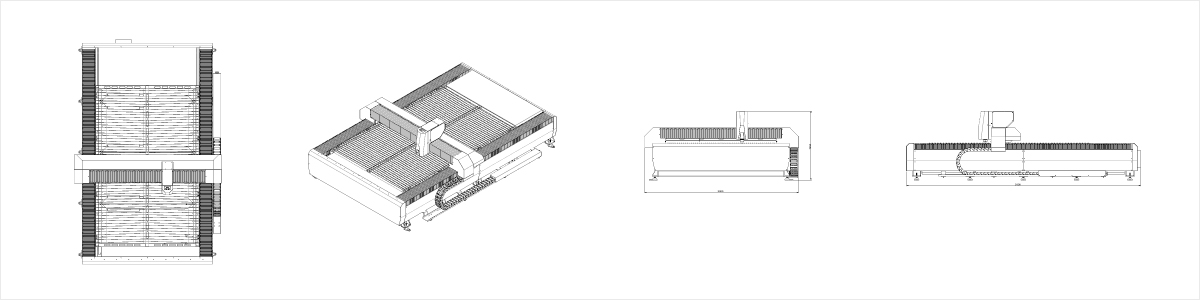

To process 4x8 size or larger discs at one time, equipment with large machining area is required.Therefore, we have developed CO2 laser equipment for base metals with machining area of 1300mm x 2500mm.

You can work on large discs of non-metallic materials such as acrylic, wood, MDF, corrugated cardboard, etc. By optimizing the laser beam path configuration, uniform machining quality is achieved throughout the machining area.

Laser is designed to select glass tube type or RF type.

All of our products can be customized according to your needs and work environment.Specification

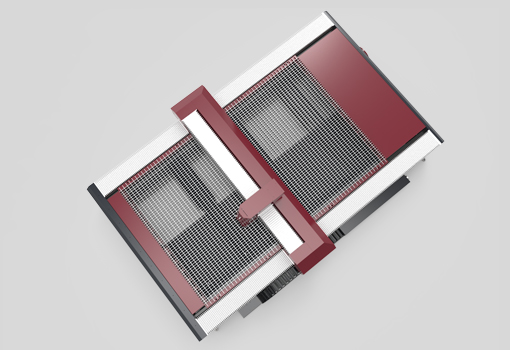

- Machining area1300 x 2500mm

- Maximum machining speed

900mm/s

- Resolution0.025mm

- Repeatability0.01mm

- CAM programE-Laser Cut 8.0

- Data input methodUSB interface direct connection, USB memory

- Supported computersOperating system Windows XP to Windows10

- Maximum cutting thickness

< 30mm (Acrylic)

- Minimum text size

English:1.5mm x 1.5mm /

Korean, Chinese:3.5mm x 3.5mm - LaserCO2 Laser 100W ~ 300W

- Data command content-only language

- Power supply

Single phase 220V 60Hz 2200W

(Domestic type) or more - Drive systemServo motor+rack & pinion+belt

Function

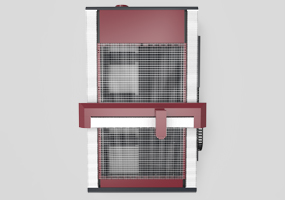

- 3 directional work

possibleAcrylic cover used to prevent danger during

processing - Precision motorApplication of high quality AC servo motor

- LCD Display

Convenient environment by changing work setting

and saving data - Multi language support

Support for multiple languages such as English,

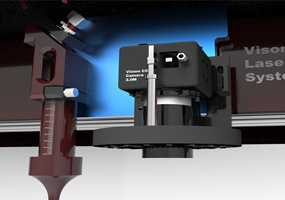

Japanese, German, Chinese - Convenient Focus Alignment

Quick and easy focus alignment with focus tool

- ACS System

Anti Corrosion System can work with pvc and

pomax - Data input methodUSB interface direct connection, USB memory

- Application of flame detection sensor

Sensor that cuts laser when flame occurs during

processing - W.A.B.E Applied technology (option)

Applied technology to produce high-quality beam

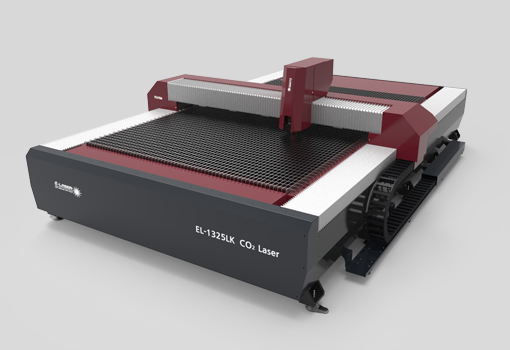

with patented optical technology - Rack & Pinion applicationDurable belt application Stable processing quality

- Various lasers availableRF(20~300W) / DC(80~180W)

- Customizing possible

Equipment modification according to user's

requirement - 1 year warrantyOur standard warranty period.

Features of equipment

-

3-way operation possible

We have cleaned out various external device wires to enable work from 3 sides.

-

High precision ball screw application

High precision ball screw is used. Precision machined ball screw minimizes misalignment and minimizes overload displacement error.

-

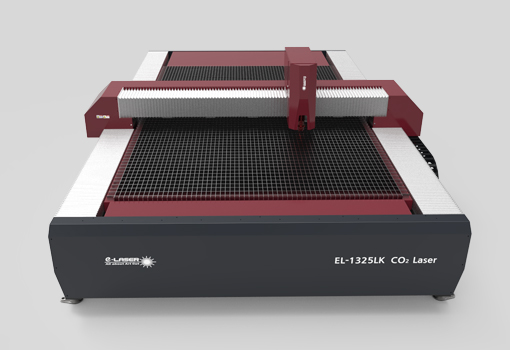

AC Servo Motor Application

Precision machining is possible by using high quality precision motors.

-

Frame structure design

Our specially designed laser head is applied. Considering laser optical properties. Completely sealed laser head.

Option

-

W.A.B.E. Apply technology

Optimized for metal surface processing by applying fiber laser of 1064nm wavelength.

In addition, various outputs can be selected from 100W to 1KW or more. -

Vision registration cutting

By applying a high performance galvanometer, we have ensured the transmission of the laser beam and the reproducibility of the quality in the machining area.

-

Select Work Table

The operation panel is configured to control only the necessary functions such as laser output, frequency, machining area setting, and scan speed

-

Selectable RF type CO2 Laser

It is composed of moving wheel + gun type to increase the equipment mobility and ease of operation